The copyright of this article belongs to Siansonic Technology.The production is prohibited without permission.

In modern manufacturing and research fields, demand for precision cleaning continues growing, with cleaning accuracy and effectiveness directly affecting product quality and performance. Megasonic clean technology, as an efficient and advanced cleaning method, stands out among many cleaning techniques by virtue of its unique cleaning principle and outstanding cleaning effect, becoming a valuable tool in the field of precision cleaning.

Megasonic clean technology makes use of ultrasonic waves with frequencies between 1 MHz and 10 MHz, which far exceed the frequency range of conventional ultrasonic cleaning (20 kHz–100 kHz). Principle of cleaning is based on cavitation and mechanical vibration of sound waves. As megasonic waves propagate through cleaning solution, they cause liquid molecules to vibrate at high frequency. Within the liquid, local low-pressure regions form due to alternating compression and rarefaction of sound waves. When pressure in a low-pressure region falls below the liquid’s saturated vapor pressure, vaporization occurs, generating tiny bubbles known as cavitation nuclei. With sound waves continuing to act, these cavitation nuclei grow and collapse—a process called cavitation effect. At the instant of bubble collapse, extremely high temperature (up to several thousand degrees Celsius) and enormous pressure (up to several hundred atmospheres) are produced, along with intense shock waves and micro-jets. These micro-jets can reach velocities of several hundred meters per second, delivering powerful impacts that dislodge contaminants from surfaces being cleaned. Additionally, high-frequency mechanical vibration of megasonic waves induces friction and collisions between cleaning solution molecules and contaminant molecules, further enhancing cleaning performance. This synergy of cavitation effect and mechanical vibration allows megasonic cleaning to penetrate minute gaps and holes, removing contaminants that conventional cleaning methods cannot reach.

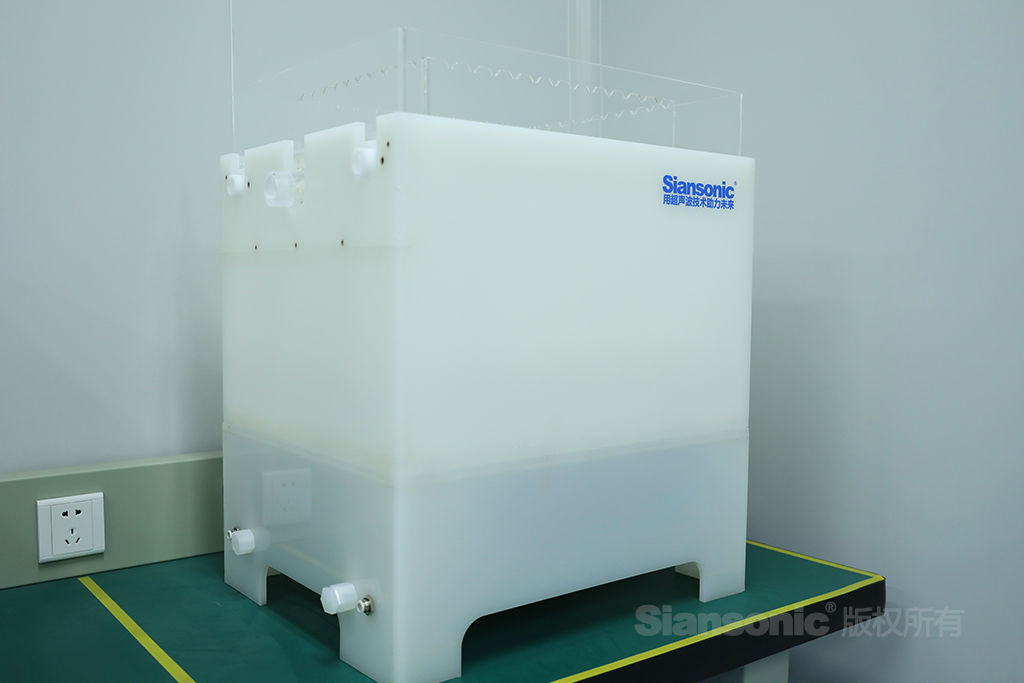

Figure 1. Siansonic's Megasonic Cleaning Tank

Contrasted with conventional ultrasonic cleaning, megasonic clean technology operates at higher frequencies, producing smaller and more evenly distributed cavitation bubbles for finer and more uniform cleaning effects. Clear advantages arise when cleaning tiny particles and precision parts; for example, in semiconductor industry, optical sector, and precision machinery manufacturing, where high cleanliness standards are required, megasonic clean technology plays a critical role.

With continuous technological advancement, requirements for product accuracy and quality keep intensifying, and with its unique advantages, megasonic clean technology promises broader application prospects. It will strongly support industry development and drive progress across various sectors toward higher precision and higher quality.